INDUSTRIAL

NITROGEN GENERATORS

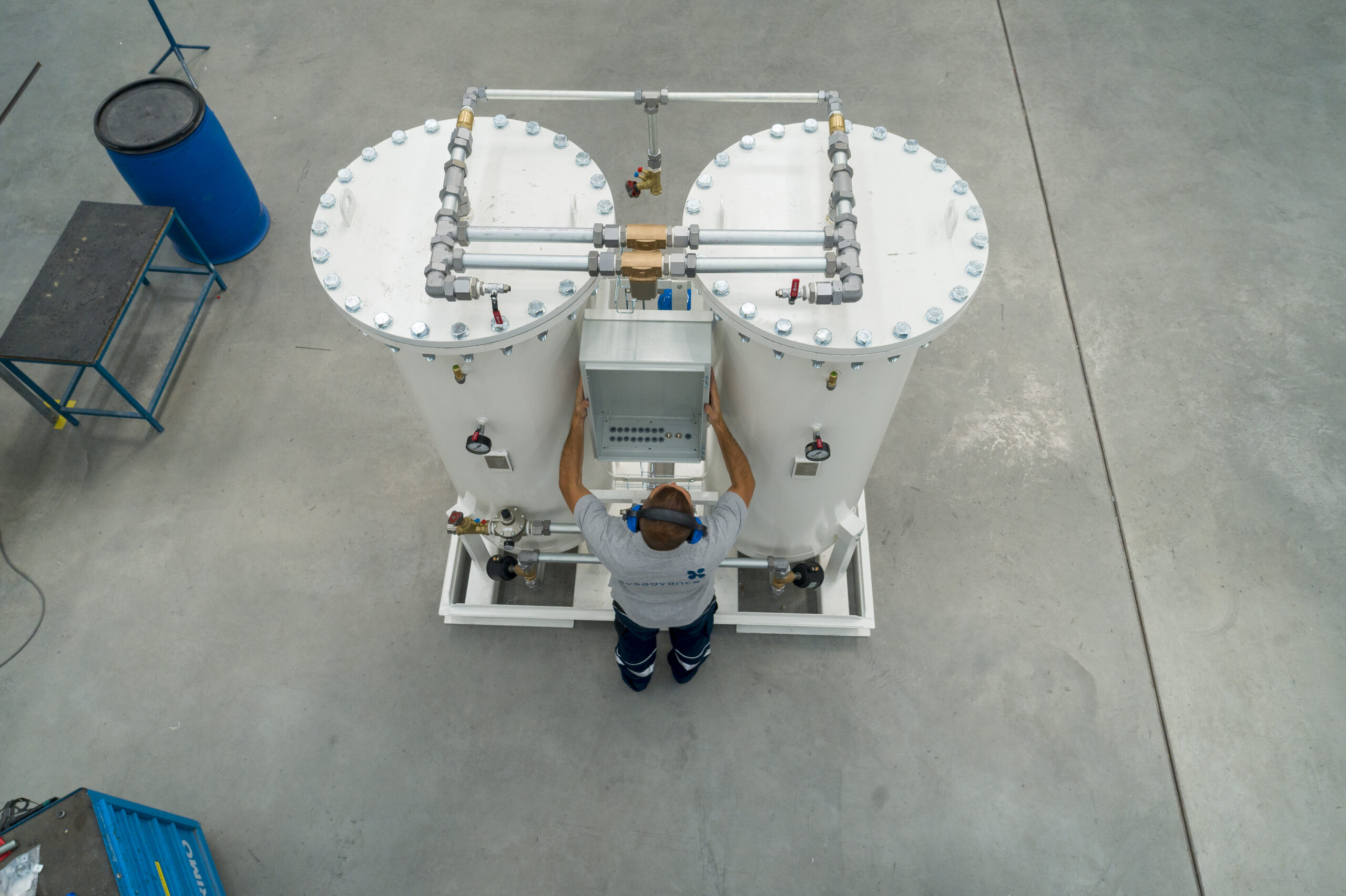

Nitrogen is designed to be easily installed in any indoor facility, requiring only a compressed air line and a power connection. The modular philosophy of SYSADVANCE Nitrogen generators allows the installation of multiple parallel units.

SYSADVANCE generators produce high purity Nitrogen from compressed air, allowing continuous availability at a very competitive cost, compared to alternative supply with cylinders or cryogenic tank.

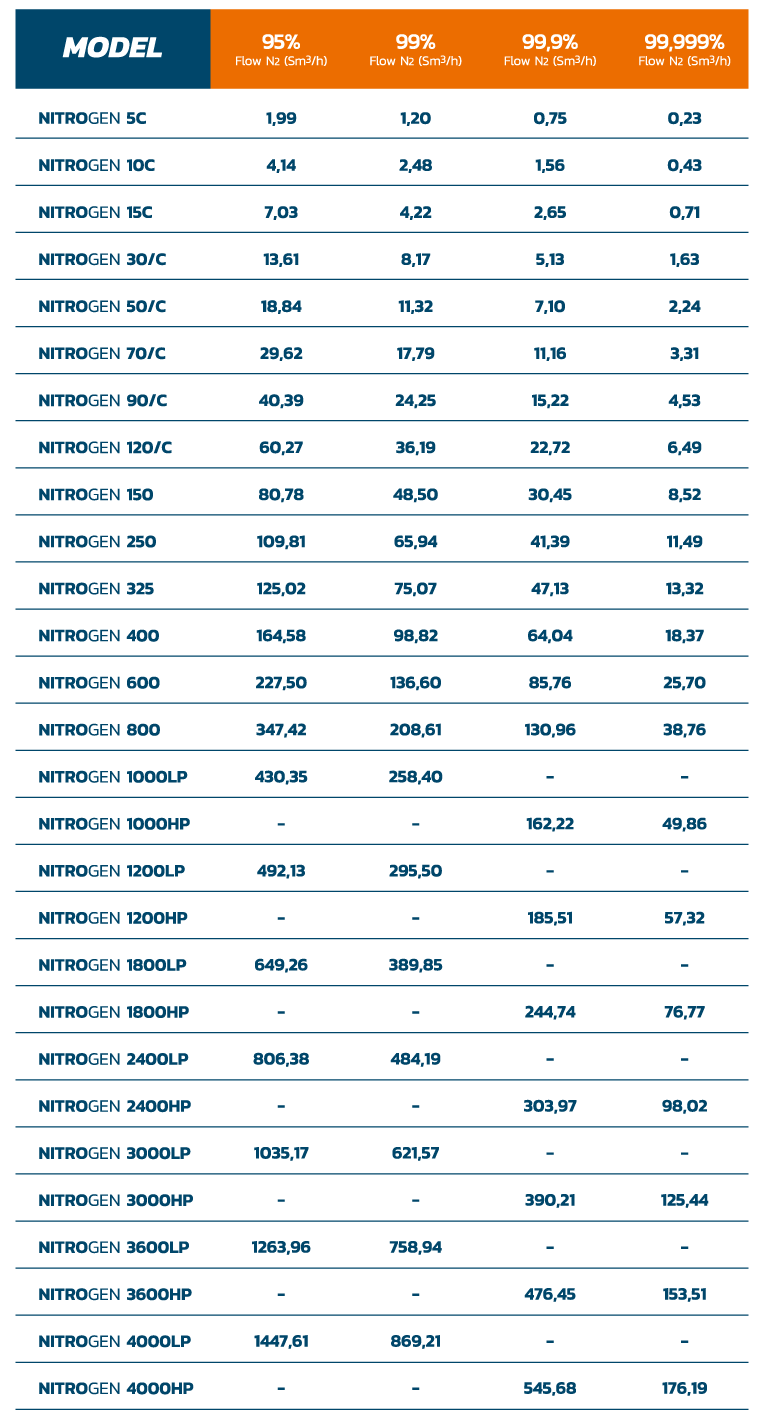

With purities up to 99.999% of N2, Nitrogen can be connected to an external buffer allowing a backup or a delay of production/consumption according to the needs of each application.

APPLICATIONS

PREPARED AND CATERED FOODS

LABORATORIES

MARINE & OFF-SHORE

HEAT TREATMENT

FOUNDRY (IRON / COPPER ALUMINIUM / ALLOYS)

WINERIES

CHEMICAL INDUSTRY

FIRE SUPRESSION

TYRE INFLATION

PHARMACEUTICALS

OIL & GAS

LASER AND PLASMA CUTTING

ELECTRONICS

Advantages

• Reduction of Nitrogen costs up to 95%

• Independence from external gas suppliers and from fluctuation of the Nitrogen market prices

• Suppression of logistic operations like handling of cylinders or liquid Nitrogen supplier management

• Modular, flexible and low maintenance units

• Nitrogen pressure up to 9 bar (without Booster)

• LCD display

• Oxygen analyzer

• 4.0 Ready

• Purity up to 99.999%

• VARIO PSA (optional)

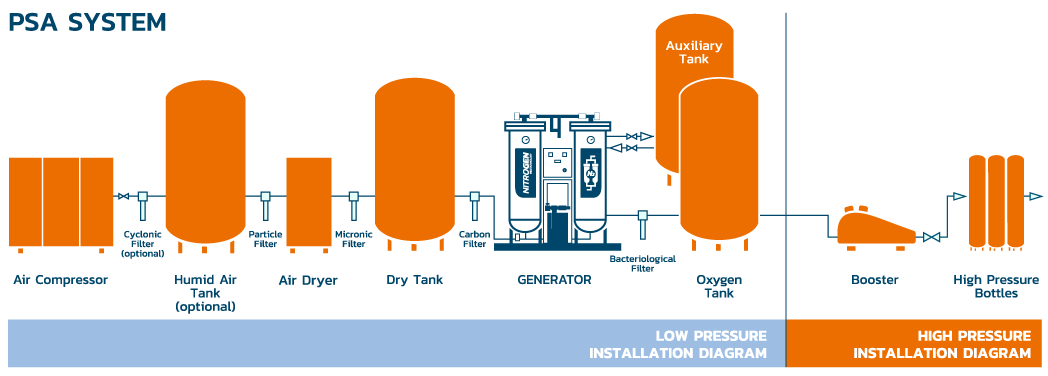

PSA Technology

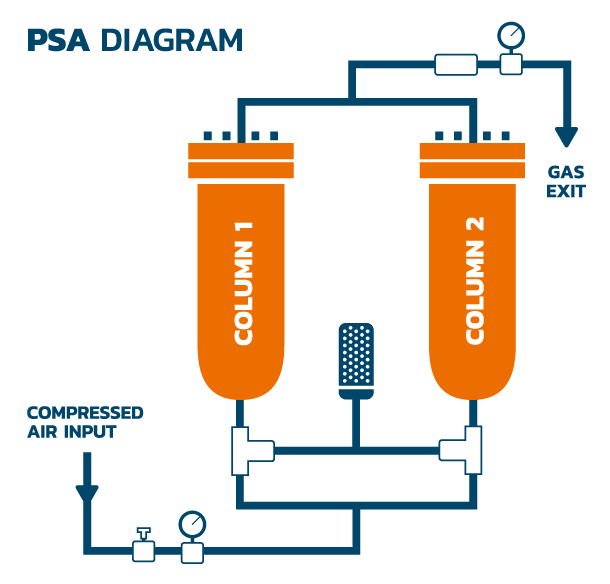

PRESSURE SWING ADSORPTION TECHNOLOGY

Pressure Swing Adsorption can be used to produce N2 or O2 from compressed air, which is fed to the unit that uses adsorption phenomena to remove the contaminants: N2 when the desired pure gas is O2, or O2 when the desired pure gas is N2. Also, in both cases, H2O and CO2 are removed as well as other minor contaminants.

The PSA unit contains two columns packed with a selective adsorbent that has affinity towards the component to be removed: a carbon molecular sieve is used to produce N2 and zeolites are used to produce O2.

Each column undergoes a cyclic sequence of high and low pressure steps that guarantees the production of a continuous flow of high purity gas.

In the high pressure step, the adsorbent retains the contaminants present in the compressed air and the desired gas (N2 or O2) is obtained from the top of the columns.

The regeneration is accomplished in the low pressure step, with the release of contaminants retained by the adsorbent.

PSA ADVANTAGES

• Economy – 90% reduction in the cost of Nitrogen

• Convenience – elimination of logistical and administrative operations

• Continuous availability – elimination of orders and deliveries

• Modularity / Scalability – your installation grows with you

• Robustness, reliability and durability

• Reduced maintenance

• Security

• Ready-to-use engineering solutions