INDUSTRIAL

HELIUM PURIFICATION

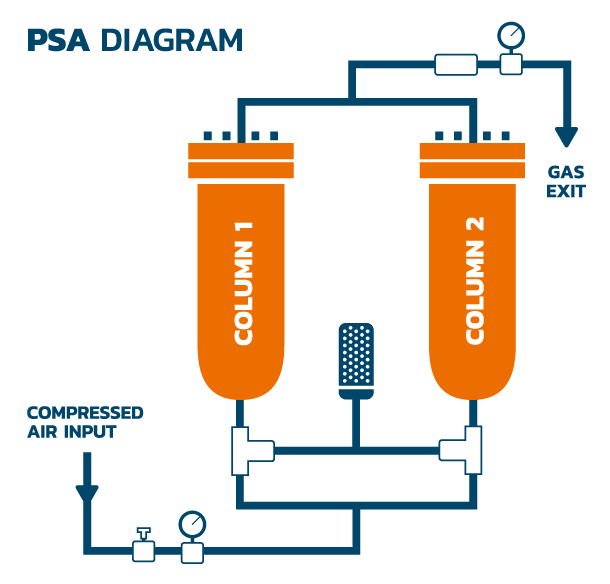

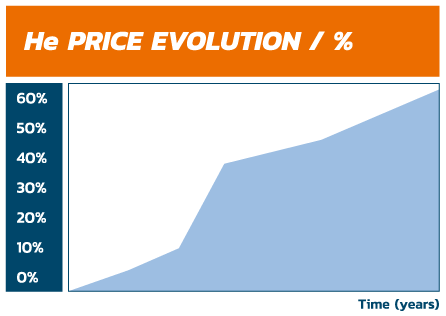

Helium has been a low price resource for many years leading to its ineficient utilization. Helium is now a scarce resource and its prices are increasing significantly.

Therefore, solutions for Helium recovery and purification are needed. Helium recovery alone is not the answer to this problem, as Helium purity decreases at each process cycle and needs to be released when minimum purity level is reached.

SYSADVANCE developed an Helium Purification System – HELISYS – using PSA technology.

These units allow to achieve high purities, high recovery rates, and huge savings in the costs associated with Helium usage.

Advantages

• Huge savings on Helium cost

• Short payback period

• High Helium recovery rates

• High and constant purity

• Also suitable for He / N2 mixtures

• Easy and quick integration with existing recovery systems

TECHNICAL SPECIFICATIONS

• Flowrates: from 2 – 1000 m3/h

• Helium purity: up to 99,9%

• Minimum Helium recovery: 95%

• Helium storage: up to 300 barg

• Power consumption: < 0.40 kWh/m3of purified Helium @ 6.5 barg

• Options: TCD Helium analyser

• Storage bag available

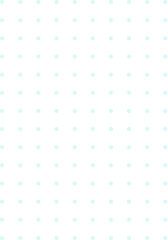

PSA Technology

Contaminated Helium is fed to the Helisys unit that uses Pressure Swing Adsorption technology to remove N2, O2, Ar, H2O and CO2.

The Helisys unit contains two columns packed with a selective adsorbent. Each column undergoes a cyclic sequence of high and low pressure steps, to produce a continuous flow of high purity Helium. The adsorbent regeneration step is assisted by a vacuum system to enhance the process efficiency.

The residual Helium desorbed during the regeneration step is recycled into the Helium baloon, resulting in minimum Helium recovery rates of 95%. The Helisys unit is fully automated and controlled by a PLC.