ENERGY

BIOXYGEN

BIOXYGEN

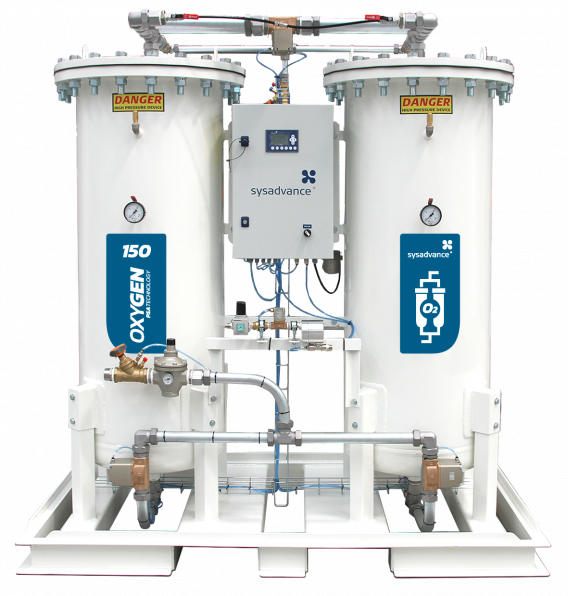

BiOXYGEN by SYSADVANCE makes use of the PSA technology to produce pure oxygen from air by selective adsorption of N2 on a special molecular sieve material. As a result, only O2 is injected in your bioprocess for H2S reduction avoiding the biogas dilution with contaminants.

A special O2 injection system developed by SYSADVANCE use proportional valves injecting O2 as a function of external process variable such as the H2S content in the raw biogas, raw biogas flow or even a combination of both is available.

Oxygen production cost per Nm3 of biogas treated is extremely low ranging from 0,0005€ to 0,0010€.

SYSADVANCE offers a wide range of O2 injection systems (PSA and VSA) covering the needs for anaerobic digestion plants with production capacities between 20 Nm3/h and 2000 Nm3/h of raw biogas.

APPLICATIONS

O2 INJECTION INTO THE HEADSPACE OF THE DIGESTER

Reduction to sulphate (H2SO4) by O2 injection into the headspace of the digester (a rate of O2 corresponding 1% of the biogas is required).

O2 SUPPLY TO BIOLOGICAL SCRUBBER

Approximately 1% of O2 is charged to the column containing the immobilized microorganisms responsible for the degradation of the H2S to sodium sulphate (NaHSO4). Sulphuric acid is formed if the rate of air injected is reduced (also suitable for trickling filters).

O2 INJECTION INTO ACTIVATED CARBON FILTERS

H2S adsorption on catalyst impregnated activated carbon requires the presence of 0.5 – 1.0% of O2 in the presence of humidity to oxidizes H2S to elementary sulphur that binds to the adsorbent surface (also suitable for iron sponge filters).

ADVANTAGES

• Safe delivery and independence from external gas suppliers and from fluctuation of the Oxygen market price;

• Suppression of logistic operations like handling of cylinders or liquid Oxygen and supplier management;

• Modular, flexible and low maintenance units;

• Low power demand – <0,5 kWh/Nm3 @ 90% O2;

• O2 purity up to 93% (dew point < -50ºC @ 0 barg);

• Compression up to 8 barg available;

• O2 sensor & output signal for remote monitoring;

• Skid or container mounted for mobility;

• VSA for larger flows and lower power demand.

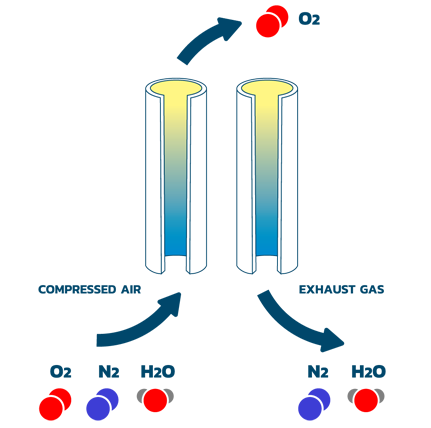

ADSORPTION TECHNOLOGY

Oxygen generators incorporate sets of columns filled with molecular sieve. Under pressure these columns retain all compounds present in air (Nitrogen, Carbon Dioxide and Water), which tie to the molecular sieve during the building of pressure, with the exception of the Oxygen. This process is known as PSA (Pressure Swing Adsorption) or VSA (Vacuum Swing Adsorption).

A modular system allows synchronized operation of several parallel units, in order to ensure a constant flow at the required purity.