ENERGY

METHAGEN | BIOGAS UPGRADING FROM ANAEROBIC DIGESTION

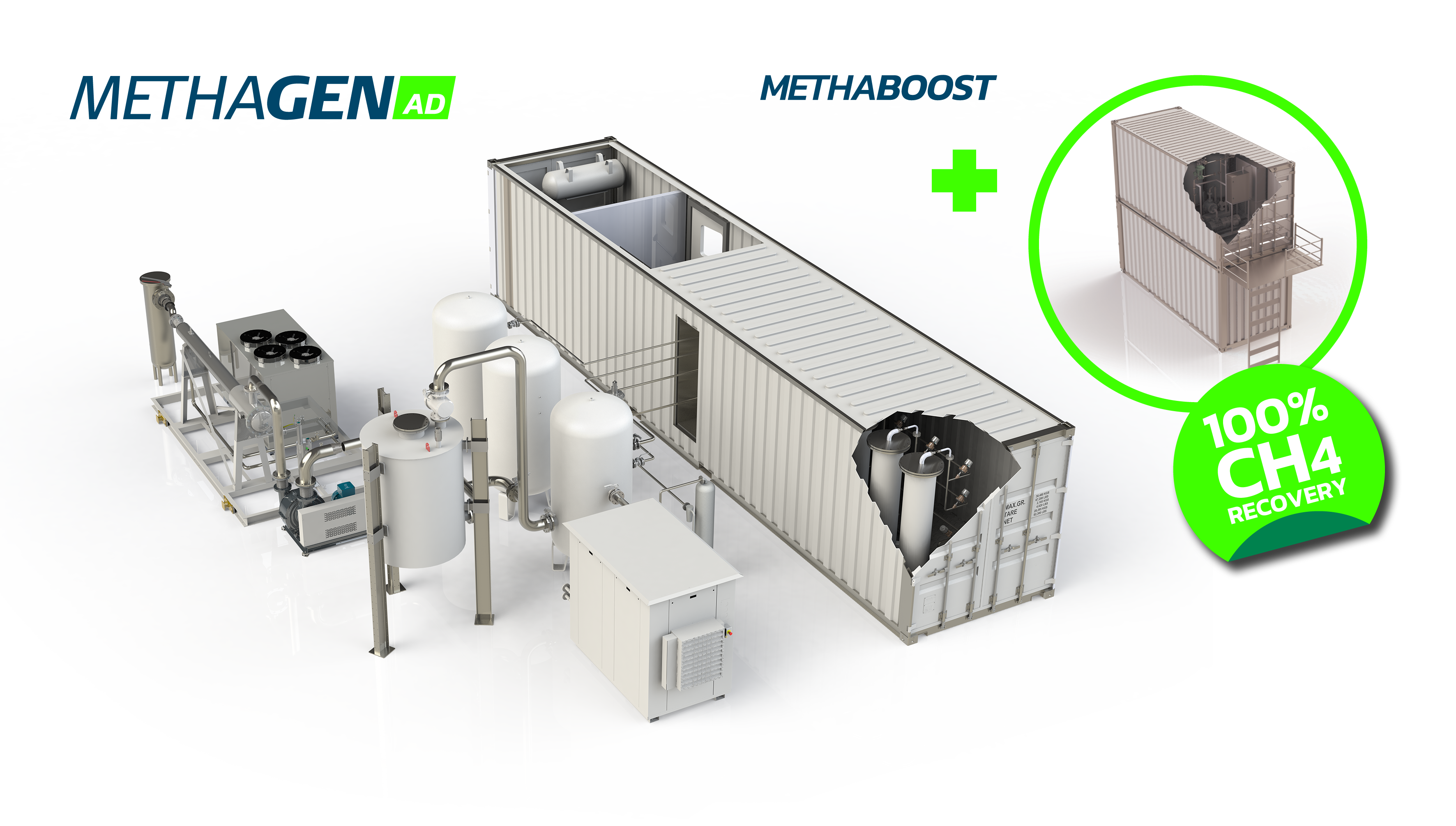

METHAGEN AD

METHAGEN AD is a system, based on VPSA (Vacuum Pressure Swing Adsorption) technology designed to purify biogas from Anaerobic Digestion feedstock like:

• Waste Water treatment plants

• Food and organic municipal waste

• Agricultural waste

METHABOOST

METHABOOST option is a post-treatment stage based on Vaccum Swing Adsorption (VSA) technology enabling the recovery of residual methane from the off-gas stream of the METHAGEN process.

METHABOOST is an efficient alternative to expensive catalytic oxidation systems, RTO (Regenerative Termo Oxidation) or low PCI boilers.

METHABOOST enables near 100% recovery, zero methane loss/emission and pure CO2 production.

METHABOOST is specially recommended for CO2 inertization of batch digesters.

Advantages

• 100% CH4 recovery > Zero emissions – METHABOOST option

• Lowest opex > 0.22 kWh/Nm3 of biogas

• Lowest capex

• High CH4 purity > up to 99%

• High recovery > up to 99,96%

• Efficient O2 and CO2 removal

• N2 reduction capability

• Dry process – no water or chemicals

• Non-cryogenic tech

• Water removal – Dewpoint < 50 ppmv H2O

• High reliability/ high availability

• Simple installation and operation

• Small footprint

• Fast plant operational readiness

• Quick start and stop

• 4.0 Enabled > remote control & dynamic reporting

• Full turnkey upgrading solution

• CO2 recovery option (CCU)

VPSA TECHNOLOGY

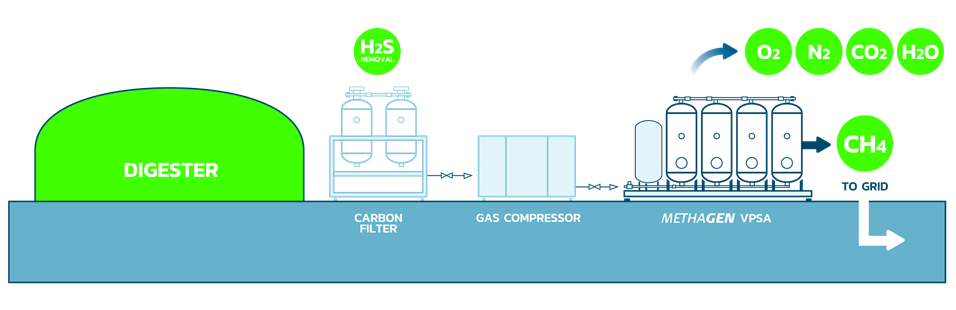

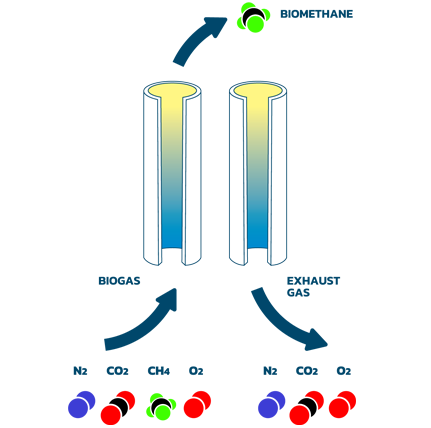

After being previously dried and desulphurized, compressed biogas is fed to the METHAGEN Upgrading Unit that makes use of VPSA technology to remove CO2, N2, O2 and residual H2O from the gas stream.

The METHAGEN system contains a set of columns packed with selective adsorbents. Each adsorption column undergoes a cyclic sequence of pressure steps, to produce a continuous flow of high-purity, dry and pressurized biomethane.

The adsorbent regeneration step is assisted by a vacuum system to enhance the process efficiency. The residual methane desorbed during the regeneration step is recycled back to the biogas inlet reservoir, resulting in a methane recovery rate close to 99%. The METHAGEN operation is fully automated and controlled by a PLC. The biomethane composition is continuously monitored by a multi-gas analysis system.

METHAGEN VPSA DIAGRAM